Checkpoint for

interval of 6 months

1) Check transformer oil

for acidity (<=0.03 mg KOH/g), sludge content (non detectable), flash point

(>=140 degree), Dielectric dissipation factor (tan delta) (<=0.010) , Interfacial tension

(>=35 mN/m) and specific resistance (resistivity) (>=6x10^12 om cm at 90 degree).

OIL ACIDITY TEST

OIL SLUDGE TEST

OIL FLASH POONT TEST

OIL TAN DELTA TEST

OIL INTERFACIAL TEST

Yearly checkpoint of Transformer

1) Check mechanical function of Buchholz

relay.

2) Marshalling box to be cleaned from

inside. All illumination, space heaters, to be checked whether they are

functioning properly or not. Check all the terminal connections of control and

relay wiring and tighten.

3) Clean all the relays,

alarms and control switches along with their circuit, in R&C panel (Relay

and Control Panel) and RTCC (Remote Tap Changer Control Panel) by appropriate

cleaning agent.

4) Check pockets for OTI & WTI (Oil Temperature Indicator & Winding

Temperature Indicator) on the transformer top cover and replace oil if

required.

5) Check proper function of Pressure Release Device.

6) Check insulation resistance and polarization index of transformer with battery

operated megger of 5 KV range.

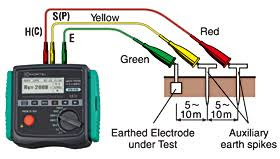

7) Check resistive value of earth connection

and rizer with clamp on earth resistance meter.

8) Check DGA (Dissolve Gas Analysis) of transformer Oil annually for

higher KV rating transformer and once in 2 years for lower KV rating

transformer.

9) Check for proper sealing of marshalling box for cable holes.

10) Check all protections and alarm circuits by actual external

initiation with relay operation.

11) Check IR value of cooling motor winding, noise and vibration of

fan.

12) Check painting and surface finish.

13) Check tightness of bolts in gasket joints.

Checkpoint for

interval of 2 years

1) Check calibration of OTI and WTI.

2) Check tan-delta measurement of bushings of transformer.

3) Check operation of gauge and healthiness of air cell.

No comments:

Post a Comment